With the continuous progress of society, the traditional agricultural production mode can no longer meet the needs of the development of modern civilization, and the new facility agriculture is sought after by people in the industry. In fact, the so-called agricultural equipment is mainly greenhouse facilities. It is not limited by time and space. It can carry out agricultural production in special environments such as plateau, deep mountain and desert. As the source of greenhouse project, materials should control the project quality, first of all, from the selection of materials. For example, for the steel components used in the greenhouse project, the high-quality steel will be processed and derusted. After hot plating in a professional galvanizing plant, the quality inspection department will test it again. After passing the test, it will be transported to the construction site for use.

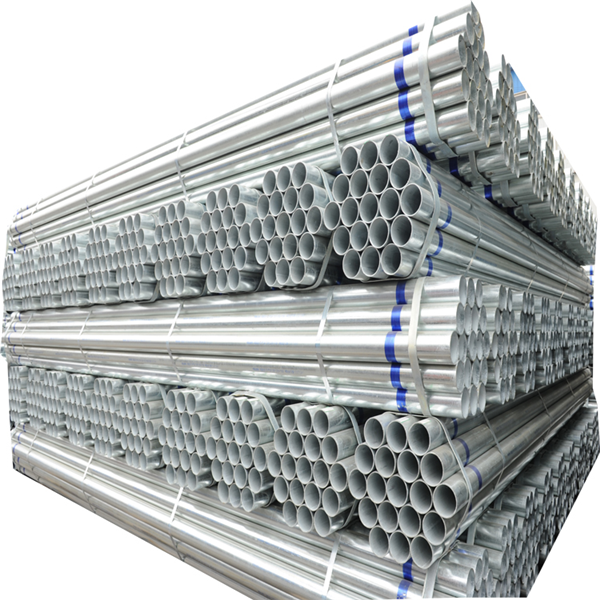

1. Hot dip galvanized steel pipe structure: hot dip galvanized pipe is to make molten metal react with iron matrix to produce alloy layer, so as to combine the matrix and coating. The hot-dip galvanized pipe supplied by Tianjin Feilong Pipe Co., Ltd. is first pickled. In order to remove iron oxide on the surface of the steel pipe, after pickling, it is cleaned in ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and then sent to the hot-dip galvanizing tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. The matrix of hot-dip galvanized steel pipe has complex physical and chemical reactions with the molten plating solution to form a corrosion-resistant zinc ferroalloy layer with compact structure. The alloy layer is integrated with the pure zinc layer and the steel pipe matrix. Therefore, it has strong corrosion resistance.

2. Galvanized strip pipe structure: galvanized strip pipe adjusts the production process of hot-dip galvanized pipe. Firstly, the strip steel used for pipe making shall be pickled to remove iron oxide on the surface of the strip steel. Then air dry and make a pipe. The coating is uniform and bright, and the amount of zinc plating is small, which is lower than the cost of producing hot-dip galvanized pipe. Its corrosion resistance is slightly worse than that of hot-dip galvanized pipe

Post time: Apr-06-2022